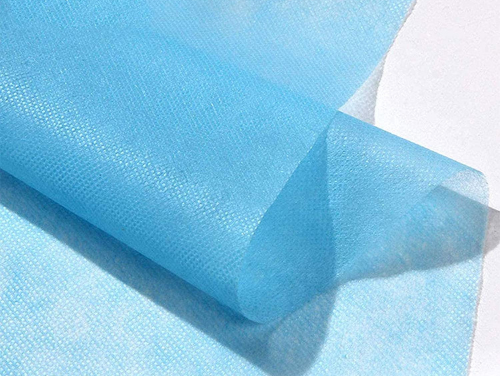

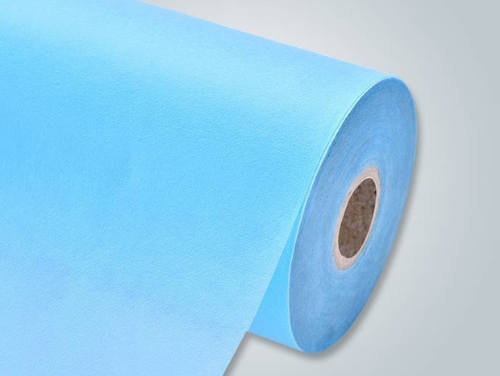

SS Spunbond Fabric

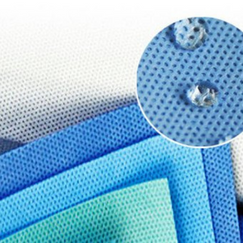

SS (spunbound+spunbound) Nonwoven Fabric is created with dual spinning beam machinery and has a considerably softer and stronger tension than PP Nonwoven Fabric. Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Shoes, and Garments are just a few of the applications for SS fabric.

Fabric Products

Detailed Information

The SS SpunBound Fabric is non-toxic, tasteless, and possesses high-efficiency isolation. It is created by hot rolling two layers of fibre net. It may achieve antistatic, anti-alcohol, anti-plasma, water, and other features by appropriate treatment of equipment and technology by us.

The antibacterial capabilities of SS non-woven fabric are unique, it does not create moths, and it can isolate the existence of germs and parasites from the incursion of fluids inside. This product is commonly used in medical care due to its antibacterial qualities. SS spunbonded non-woven fabrics are currently widely employed in a variety of industries, including textiles and clothing, ornamental materials, and medicinal and health products, due to their unique utility.

It can be used to increase the quality stability of completed products such as baby diapers, paper diapers, sanitary napkins, adult diapers, and hospital sanitary products (non-woven series such as sanitary pads, masks, protective garments, and so on).

Key Attributes

Fabric Products

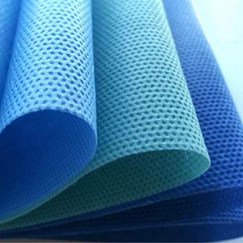

SS nonwovens are softer than other nonwovens and are made from polypropylene. Because they are constructed of several fine strands, SS microfiber spunbonded melt blown nonwoven fabrics are bulkier and more skin pleasant than cotton. All fine fibre goods have a high air permeability, which keeps the cloth dry and easy to clean.

- High tensile strength and durability.

- Antibacterial properties making it suitable for medical care.

- It is water resistant and is breathable.

- It is anti-chemical and suitable for sensitive skin.

- It is non-toxic and hence environmentally friendly.